Professional Summary

With 7+ years of experience in Electrical Engineering and Industrial Automation, I specialize in designing, implementing, and optimizing control systems. My expertise includes PLC programming, HMI development, industrial networking, and electrical system design, ensuring efficient and reliable automation solutions. I have successfully led and contributed to multidisciplinary projects, collaborating with engineers, clients, and stakeholders to deliver high-performing, compliant, and scalable systems.

My work has consistently resulted in cost reductions, increased efficiency, and improved safety, demonstrating a strong ability to analyze technical challenges and implement effective solutions. Whether developing new automation systems or refining existing processes, I am committed to innovation, reliability, and continuous improvement, ensuring that systems meet both current and future operational demands.

Skills

Programming

I have experience in programming of industrial programmable Logic controllers. I have used all of the IEC 61131-3 programming languages:

- Ladder Logic

- Structured Text

- Function Block Diagrams

- Sequential Flow Charts

- Instruction Lists

Hardware and Technologies

I have completed projects using several different types of controllers, drives and components including:

- OMRON PLCs including CP1L, CP2E, ZEN

- Allen Bradly PLCs such as Micro830

- IFM AS-I Controllers such as AC422S and AS-I modules such as AC030S

- TURCK Industrial Ethernet I/O Modules such as FEN20-16DXP

- Variable Speed Drives (VSD) such as OMRON MX2 inverter and Lenze i510 Drive Configuration.

- Human Machine Interface (HMI) such as OMRON NB Series.

- Industrial Electrical Components such as Industrial Sensors, Actuators, Relays, Timers, Contactors, Circuit Breakers and Overloads.

Software

- CODESYS

- OMRON CX-One Suite

- Allen Bradly CCW

- AutoCAD Electrical

- EPLAN Electric P8

- SISTEMA

- Fusion 360

- OrCAD

- TURCK ARGEE v3,

- Visual Studio Code

- Microsoft Office Suite.

Hardware Design

I have experiance with Electrical Hrdware design such as Electrical Schematic Design, Electrical Panel Layout, Component Selection, Component Sizing Calculations, Component Setup and configuration, Prototyping, Commissioning and Testing and Troubleshooting.

Engineering standards

In my engineering design Activitties, I have work with several local and international engineering standards such as

such as AS3000, AS4024, AS1735, IEC 61131-3 and IEC 61508.

Work History

I have experience in industrial automation and electrical engineering and have worked across multiple industries, including materials handling, CNC machining, and manufacturing. Throughout my career, I have taken on diverse technical roles, designing and implementing automation solutions, optimizing electrical systems, and ensuring compliance with industry standards. My ability to work both independently and collaboratively within multidisciplinary teams has allowed me to contribute effectively to complex engineering projects. This section highlights my professional journey, showcasing the key roles and contributions I have made in each position.

Systems Engineer

ANCA Pty Ltd

Mar 2024 – Present

I am proud to be part of ANCA CNC’s New Product Development (NPD) team, contributing to the design and integration of cutting-edge CNC grinding machines. ANCA is a world leader in precision tool grinding technology, with a strong reputation for innovation in automation, motion control, and software development. My role involves the electrical and control system design of advanced manufacturing equipment, where I apply my expertise in industrial automation, PLC programming, and system integration. Working alongside a multidisciplinary team, I play a key role in developing next-generation solutions that enhance machine performance, reliability, and automation capabilities.

Key Responsibilities:

- Electrical and Automation Design: Design and develop electrical systems for CNC grinding machines, ensuring cost-effectiveness, manufacturability, and reliability.

- Control System Integration: Implement and validate PLC logic, low-level software, and automation controls for machine tool applications.

- Software Development & Commissioning: Develop, test, and deploy machine control software using ANCA PLC and managing version control via Git.

- Bill of Materials (BOM) Management: Prepare accurate and up-to-date BOMs to support product lifecycle and manufacturing processes.

- Cross-functional Collaboration: Work closely with branches, customers, and internal teams to define technical requirements and provide engineering support.

- Compliance & Standards: Apply European CE Directives and safety regulations throughout the product development cycle.

- Technical Support & Troubleshooting: Assist manufacturing, applications, and service engineers with system validation, troubleshooting, and optimisation.

- Project Planning & Analysis: Provide detailed time estimates, financial analyses, and technical documentation to support new product initiatives.

This role allows me to contribute to innovative engineering solutions in a high-tech manufacturing environment, ensuring ANCA remains at the forefront of CNC machine tool technology.

Electrical Design Engineer

Capstone Industries Pty Ltd

Oct 2018 – Feb 2024

I thoroughly enjoyed my role as the Electrical and Automation Engineer at Capstone Industries, where I had the opportunity to work on a diverse range of material handling equipment, including scissor lift tables, freight hoists, dock levelers, vehicle restraints, inflatable seals, traffic light systems, and more. This position allowed me to apply my technical expertise in electrical design, programming, and automation while taking full ownership of projects from concept to completion. I found great satisfaction in overseeing installations, testing, and commissioning, ensuring that each system met the highest standards of performance and reliability.

Beyond new designs, I also played a key role in upgrading existing material handling equipment such as car stackers, bale presses, cardboard crushers, and compactors, helping to extend their lifespan and improve functionality. Over my tenure, I successfully delivered the electrical and electronics design for more than fifty projects, making a tangible impact on efficiency, safety, and overall system performance. This experience deepened my passion for industrial automation and strengthened my ability to solve complex engineering challenges.

At Capstone Industries, my main responsibilities included:

- Designing, simulating, and testing electrical and control systems used in Capstone products.

- Creating electrical schematics and designing electrical panel layouts.

- Developing software for Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and Variable Speed Drives (VSDs).

- Developing test procedures for both hardware and software validation.

- Ensuring that electrical wiring and installations conformed to best practices and standards such as AS/NZS 3000, while implementing proper control and protection methods.

- Designing Safety Instrumented Systems and interlocking circuits (e.g., door and gate interlocks) in compliance with AS/NZS 4024 – Safety of Machinery and IEC 61508 (Functional Safety of E/E/PE Systems).

- Commissioning electrical systems and ensuring optimal performance.

- Creating Bills of Materials (BOMs) for procuring electronic and electrical components used in Capstone products and systems.

- Developing technical documentation, including internal product documentation and external materials such as owner’s manuals, installation guides, maintenance manuals, operating instructions, and signage.

- Interpreting specifications, drawings, standards, and regulations to ensure compliance.

- Collaborating with vendors such as OMRON, Intercel, Balluff, Schneider Electric, IFM, and Pepperl+Fuchs to develop automation and control solutions.

- Providing on-site assistance to field technicians in troubleshooting and resolving electrical issues.

Impact

- Introduced professional software such as AutoCAD Electrical, significantly improving the documentation of electrical designs. This also reduced project completion times by enabling the production of high-quality electrical drawings and panel layouts for electricians.

- Implemented inspection test sheets and factory acceptance tests for electrical wiring on equipment as part of quality control. This led to approximately 30% fewer warranty issues related to electrical wiring.

- Integrated 4G modules with PLCs, enabling remote programming, monitoring, and maintenance of equipment, eliminating the need for on-site visits. These gateways also allowed machinery to send email and SMS notifications when specific conditions occurred.

- Introduced Actuator Sensor Interface (AS-I) as a wiring solution for the attendant freight hoist, eliminating the need for long lengths of multi-core cables between controllers and field devices. This resulted in reduced wiring, faster installation times, and more manageable systems that were easier to maintain and upgrade.

Systems Analyst

NCR (National Cash Register) Voyix Corporation

Aug 2018 – Sept 2018

This role as a Systems Analyst at NCR was an exciting first work opportunity in Australia, where I gained valuable hands-on experience in the financial technology sector. Despite being a short-term position, it provided me with an excellent introduction to the technical and operational aspects of Automated Teller Machines (ATMs) and EFTPOS systems. I enjoyed working in a fast-paced environment, contributing to critical system upgrades and maintenance tasks that ensured seamless financial transactions for end users. This role allowed me to refine my troubleshooting skills, gain insight into high-reliability electronic systems, and collaborate with a skilled team of professionals.

Unfortunately, my time at NCR was brief, as the company decided to move its operations to another state. However, within that month, I learned a great deal about hardware and software integration, quality control processes, and the importance of rigorous testing in mission-critical systems. The experience strengthened my adaptability and reinforced my passion for automation and system optimization.

Key Responsibilities:

- Installed, configured, and customized software for new ATM and EFTPOS units.

- Assembled and tested units to ensure quality before deployment.

- Performed preventive maintenance and refurbishments on EFTPOS terminals and ATMs.

- Upgraded systems to support new banknotes and banking requirements.

- Conducted failure analysis and implemented corrective actions for faulty terminals.

- Reviewed and validated upgraded units to ensure compliance with quality standards.

Electronics Engineer

Mine Health and Safety Council

Jan 2017 – June 2018

I had the opportunity to be part of a cutting-edge Research and Development (R&D) project, led by the University of Pretoria for the Mine Health and Safety Council of South Africa. The project focused on developing an underground Power Line Communication (PLC) system, which enabled communication in mines through Wi-Fi access points integrated with power lines. This role allowed me to be at the forefront of technological innovation and helped me develop invaluable skills in the field of electrical engineering and communication systems.

Key Responsibilities:

- Designed and simulated circuits for coupling RF signals onto AC power lines.

- Developed PCB layouts for frequency conversion circuits used in the system.

- Assembled and soldered prototype circuits for testing and evaluation.

- Designed and conducted experiments to assess prototype performance.

- Created Bills of Materials (BOM) and managed procurement of electronic components.

- Documented technical details, prepared progress reports, and contributed to project presentations.

- Diagnosed and repaired printed circuit boards (PCBs) by replacing faulty electronic and mechanical components.

Assistant Lecturer

University of Pretoria

Jan 2017 – June 2018

I was thrilled to be appointed as an Assistant Lecturer at the University of Pretoria, where I had the incredible opportunity to teach multiple undergraduate engineering modules. I taught Modulation Systems (EMS 310) to third-year students and Electricity and Electronics (EBN 122) and Introduction to Laboratory Measurements and Computer Simulations (EMR 101) to first-year students. This role allowed me to share my knowledge and enthusiasm for engineering with eager minds. It also honed my communication and leadership skills, as I guided students through complex concepts, conducted practical sessions, and mentored them throughout their academic journey. It was an enriching experience that deepened my own understanding and solidified my commitment to the future of engineering education.

Key Responsibilities:

- Delivered lectures and facilitated discussions on course material.

- Developed, set, and marked tests and assignments.

- Trained and guided evaluators for practical sessions.

- Assisted students during laboratory practicals and tutorials, ensuring a thorough understanding of key concepts.

Education

A solid education has been the cornerstone of my growth as an engineer. The knowledge and mentorship I received from lecturers and teachers have played a crucial role in shaping my technical expertise and problem-solving approach. Each course, project, and challenge has contributed to a deep understanding of industrial automation, electrical design, and system optimization. Standing on the shoulders of those who taught me, I continue to build upon this strong foundation, applying what I’ve learned to innovate and solve real-world engineering challenges.

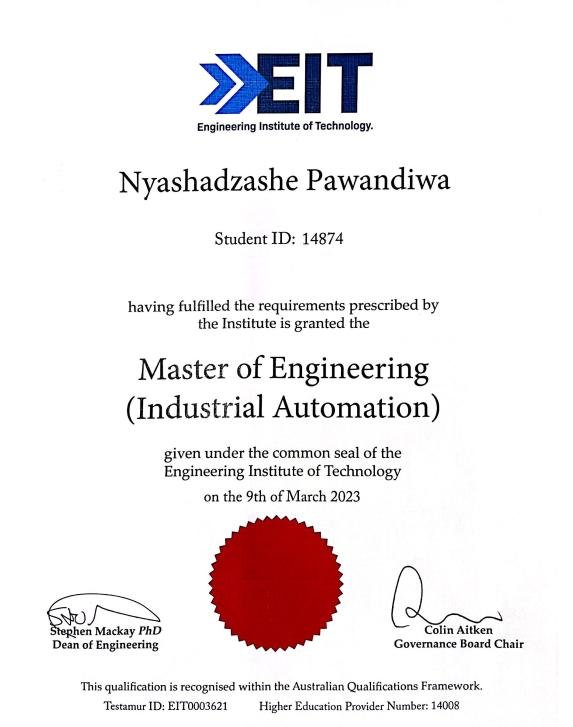

Masters of Engineering – MEng Industrial Automation

Engineering Institute of Technology – Australia

Graduated in 2022

Completed a Masters Degree in Industrial Automation with the Engineering Institute of Technology (EIT).

Thesis: A Power Line Communication Implementation Of The Actuator Sensor Interface (As-I) Fieldbus For Remote I/O.

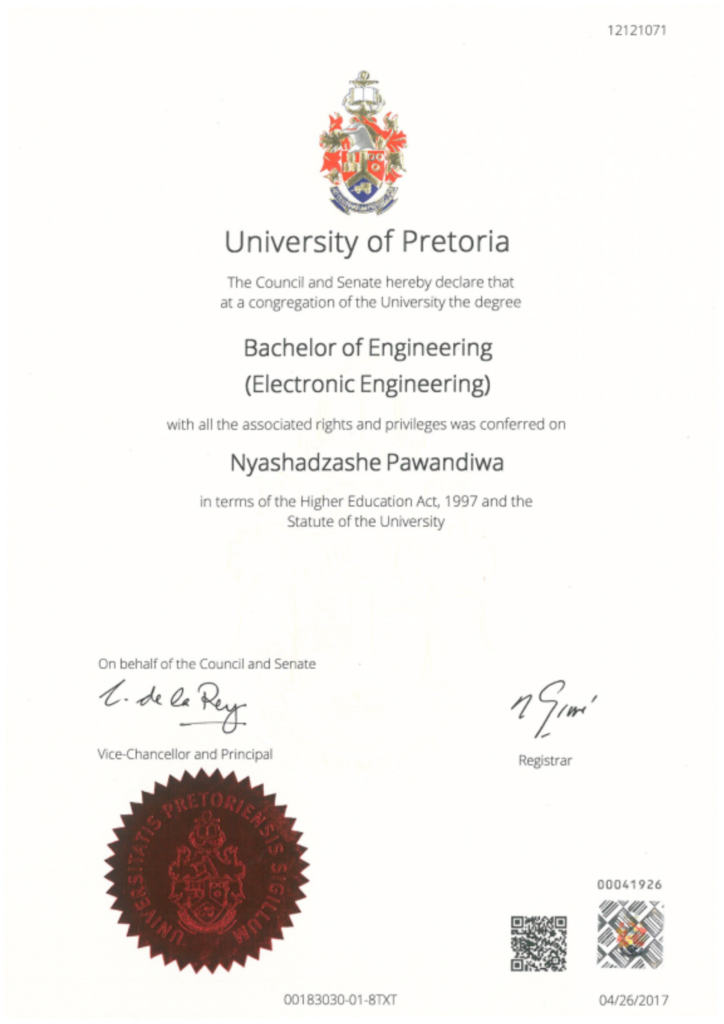

Bachelor of Engineering (Honours) – BEng (Hons) Electronic Engineering (With Distinction).

University Of Pretoria – South Africa

Graduated in 2017

Completed an Honours Degree (With Distinction) in Electronic Engineering at the university of Pretoria.

- Awarded the Academic Honorary Colours by the Student Representative Council (SRC) at the University of Pretoria.

- Awarded the 2017 NRF Honour Innovation scholarship by the National Research Foundation (NRF).

Bachelor of Engineering – BEng Electronic Engineering.

University Of Pretoria – South Africa

Graduated in 2016

Completed an Undergraduate degree in Electronic Engineering with modules such as Control systems, Industrial Automation, Programming, Microprocessors, Telecommunications and Analog and Digital Electronics.

- Awarded the new undergraduate achievement bursary by the University of Pretoria (2012).

Bachelor of Engineering – BEng Electronic Engineering.

University Of Pretoria – South Africa

Graduated in 2016

Completed an Undergraduate degree in Electronic Engineering with modules such as Control systems, Industrial Automation, Programming, Microprocessors, Telecommunications and Analog and Digital Electronics.

- Awarded the new undergraduate achievement bursary by the University of Pretoria (2012).